Cutting supply chain emissions is one of the biggest levers companies have to meet their climate goals. But most companies are still stuck at the starting line - held back by data gaps, complexity, and limited supplier engagement.

The message from our recent LFCA Learning Session was clear: you don’t need perfect data to start driving real progress. Whether you’re at the beginning of your Scope 3 journey or refining your supplier strategy, there are practical ways to take action today.

Here are the key takeaways our Climate Expert, Irene Colaboni, shared:

1. Start with what you know

You don’t need full supplier-specific data to begin. The GHG Protocol allows for different estimation methods—including spend-based, activity-based, and supplier-specific approaches. Start by using the data you already have—such as procurement records, product categories, or purchase volumes—to create a baseline.

🔍 If you don’t yet know your company’s largest upstream emitters, use sector-specific Scope 3 breakdowns (e.g. SBTi’s) or benchmarks to estimate where the hotspots are likely to be. For example:

In tech, emissions often concentrate in semiconductors, hardware, and cloud infrastructure In fashion, key categories include textiles, dyeing/finishing, and raw material sourcing

In construction, high-impact materials include steel, cement, and glass

In services, emissions may come mostly from purchased IT, business travel, and marketing services

🎯Once you’ve identified likely hotspots, prioritize those categories for deeper analysis, supplier engagement, or procurement interventions—even if your initial estimates are rough. The goal is to take meaningful first steps while improving data over time.

2. Prioritize Tier 1 Suppliers

Tier 1 is where companies typically have the most influence. Begin with strategic suppliers or those where you have strong relationships. Embed climate expectations into sourcing decisions, contracts, and onboarding processes.

For example, some of our members are:

Adding climate clauses to supplier agreements

Offering better payment terms to sustainable suppliers

Setting minimum standards for carbon reporting

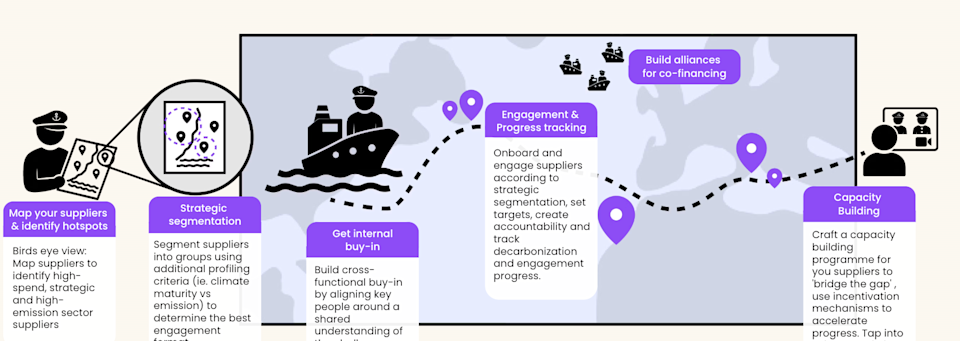

3. Segment suppliers for smarter engagement

Suppliers vary in their sustainability maturity. Use surveys, ESG scores (like EcoVadis), or internal assessments to group suppliers and tailor your engagement:

Emerging → Share training and tools

Intermediate → Support carbon measurement & reporting Advanced → Co-create low-carbon solutions

This approach helps allocate limited resources more effectively and increases your overall impact.

Use a mix of criteria to prioritise suppliers for engagement, naturally including their estimated GHG emissions but also evaluating other factors such as

the strategic importance to your business

the supplier’s maturity on climate literacy and action readiness

the level of influence and leverage your company has

insights from procurement teams on relationship strength, contract timing, and co-investment opportunities

Priority should be given to those suppliers with the most significant potential for emission reduction and fewer potential challenges.

🎯 Start small but strategic: work with a handful of key suppliers to build momentum, then scale as systems and learnings grow. Ask our Climate team for case studies on supplier prioritisation from across our community 🧐

4. Bring Procurement into the climate conversation

Procurement is a powerful ally—but often underutilised. Help them understand how climate goals link to purchasing decisions. Provide clear criteria, training, and tools to embed sustainability into day-to-day workflows.

Other key teams to include are:

Legal (to update contract language)

Finance (to support incentives and carbon pricing)

Leadership (to signal urgency and direction)

🛠 Provide practical tools: training, supplier questionnaires, checklists, and internal carbon pricing frameworks. Aligning commercial and climate goals is key to long-term success! LFCA can also deliver custom, team-specific training with best-practice & benchmarking for your industry.

5. Data and action can advance together

Think of data quality and decarbonisation as parallel journeys - not sequential steps.

As the SBTi and CDP both emphasize: companies can and should act using estimates, as long as there’s a clear plan to improve data and scale engagement moving forward.

Engaging suppliers early - even using estimates - can:

Improve your data quality through shared disclosures

Strengthen supplier relationships

Lay the foundation for joint reduction plans

💬 One member put it nicely: “When we began engaging suppliers, our data actually got better. Action and measurement reinforce each other.”

6. Use Collective Leverage to Accelerate Change

If you lack leverage with suppliers, partner with others. Whether through existing alliances or informal peer networks, shared engagement reduces supplier fatigue, increases alignment, increases supplier pressure and helps normalise expectations across industries.

There are two main ways members are using collective leverage:

🛠️ Join or align with sector-wide alliances

These initiatives enable buyers to share resources, set common expectations, and - in some cases - jointly invest in low-carbon solutions. Some examples include:

Textile Exchange (fashion): Drives standardization and shared tools across materials and manufacturing

Open Compute Project (tech): Promotes collaboration on low-carbon hardware design and procurement

ZEMBA / SABA (cross-sector): Coordinate large-volume procurement of near-zero emissions materials like steel and aluminum

Clean Energy Buyers Association (CEBA) and 1.5°C Supply Chain Leaders also offer platforms for aligned action in specific sectors.

These alliances often reduce the burden on suppliers and send a clear market signal that low-carbon performance is now a competitive requirement.

📊 Use shared disclosure platforms like CDP Supply Chain

CDP Supply Chain enables multiple customers to request the same supplier climate data - at scale.

Over 330+ organizations use it to engage suppliers, covering more than 47,000 suppliers globally

Suppliers submit one standardised response to meet requests from multiple customers

This saves time, improves response rates, and helps buyers identify risks and opportunities using comparable metrics.

🤝 Even informal coordination—sharing questionnaires or engaging a supplier jointly—can create momentum and increase efficiency. LFCA actively facilitates informal relationships per sector within our community - please let us know if you would like some introductions.

The Path Forward

Supply chain decarbonisation isn’t just a data problem - it’s a mindset shift. It requires early action, strategic focus, and a willingness to learn alongside your suppliers.

LFCA is actively collaborating with members to build and strengthen strategic alliances, recognising that today’s fragmented supplier base and varying readiness levels require coordinated, scalable solutions. With the recent addition of custom elements to our LFCA app, we are also enhancing supply chain capacity-building efforts, making supplier engagement more efficient and cost-effective - even when contracts are short-term, supplier readiness differs or supply-chains are highly fragmented.

As one participant put it: “our suppliers are part of the solution - not just part of the footprint”

📚 Want to go deeper?

Join our upcoming Climate Transition & Supply Chain Decarbonisation short course (starts 18th September, applications closing shortly), or schedule a short call with us to explore how LFCA can help accelerate your supplier decarbonisation journey with our road-tested, scalable approaches.